Where should LED lighting fixtures not be used?

LED lighting technology has become a mainstream choice for modern home and commercial lighting due to its numerous advantages, including high efficiency, energy saving, long life, and environmental friendliness. While LED lighting offers significant advantages in many applications, it's not always suitable.

The operating principles, installation methods, and environmental characteristics of LED lighting fixtures mean they may not be suitable for certain environments and may even pose safety hazards or produce poor lighting effects. When choosing LED lighting, we need to consider multiple factors, including environmental conditions, fixture characteristics, and usage requirements.

This article will explore in detail where LED lighting is not suitable and provide specific recommendations to help consumers and businesses make informed choices.

What are the characteristics of LED lighting?

Before exploring areas where LED lighting is not suitable, we first need to understand some basic characteristics of LED lighting. LEDs (light-emitting diodes), as semiconductor light sources, operate on principles that differ significantly from traditional incandescent and fluorescent lamps. LED lighting fixtures primarily emit light by stimulating semiconductor materials with an electric current, offering the following advantages:

• High energy efficiency: LED lighting fixtures are significantly more energy-efficient than traditional lighting fixtures such as incandescent and fluorescent lamps, with conversion efficiencies exceeding 90%.

• Low heat generation: Compared to traditional lamps, LED lamps generate very little heat, reducing the environmental impact of heat buildup.

• Long lifespan: LED lighting fixtures can last up to 25,000 to 50,000 hours, significantly longer than incandescent and fluorescent lamps.

• Environmentally adaptable: LED lighting fixtures can operate at lower temperatures, making them suitable for more extreme environments.

What are the limitations of LED lighting?

However, despite their many advantages, LED lighting also has some limitations. The following are some factors that may affect the use of LED lighting:

• Operating temperature: While LED lighting fixtures can operate at lower temperatures, their performance may be affected in high-temperature environments.

• Voltage requirements: LED lighting fixtures require high voltage stability. Excessive voltage fluctuations may damage the LED lamp or cause unstable operation.

• Strong light directionality: LED light beams are usually more concentrated, so they may not be suitable for places that require wide and uniform lighting.

Based on this, we can further analyze which places are not suitable for using LED lighting.

Where should LED lighting be used?

1. Extremely high temperature environment

Although LED lighting fixtures generally have good low temperature adaptability, the performance of LED lights may be affected in extremely high temperature environments. LED lighting fixtures usually have built-in heat dissipation devices to reduce heat, but if the working environment temperature is too high, the heat dissipation effect may be insufficient, which will shorten the service life of the LED lights and even cause premature failure.

(1) High temperature factories: Some high temperature industrial environments, such as smelters, glass manufacturing plants and some chemical processing plants, have extremely high operating temperatures. In such environments, LED lighting fixtures are not only difficult to dissipate heat effectively, but may also cause damage to the lamps or safety hazards due to overheating. Therefore, in these high temperature environments, LED lighting is not an ideal choice.

(2) Hot outdoor environment: In some areas, especially in hot deserts and tropical regions, the outdoor environment may exceed 40℃ in summer. The heat dissipation system of LED lighting fixtures may lose its effectiveness in such high temperature environments. Therefore, LED lighting fixtures exposed to such environments for a long time may degrade or malfunction prematurely.

2. Humid or submerged environment

Although the circuit structure of LED lighting fixtures has moisture-proof properties to a certain extent, the electronic components of LED lights may be damaged if they are exposed to humid environments for a long time, especially in places with heavy water vapor or frequent flooding. The corrosion of electronic components by moisture will affect their performance and may even cause short circuits or safety accidents.

(1) Humid basements or warehouses: Some basements or warehouses have high humidity and high moisture content in the air. This environment poses a greater risk of corrosion to LED lighting fixtures, especially some ordinary LED lighting fixtures without waterproof design. Therefore, in these humid places, LED lighting fixtures with higher waterproof and moisture-proof grades should be selected or other lighting equipment should be considered.

(2) Places subject to long-term water immersion: Ordinary LED lighting fixtures may not be suitable for use in pools, swimming pools, and other places that are in contact with water for a long time. Although some LED lighting fixtures with higher waterproof ratings can be used underwater, most LED lighting fixtures do not have this capability. Especially when working in a water-immersion environment, the LED lights may malfunction or even short-circuit.

3. Areas with unstable voltage

LED lighting fixtures have high requirements for voltage stability. In places with large voltage fluctuations, LED lighting fixtures may not work properly or may even burn out due to excessively high or low voltage. Ordinary LED lighting fixtures may not be suitable for places with unstable power grids or uneven voltages.

(1) Areas with unstable power supply: In some areas with unstable power supply, the voltage fluctuates greatly, and this environment will affect the service life of LED lighting fixtures. Although modern LED lighting fixtures usually have a certain voltage protection design, long-term voltage fluctuations can still cause damage to LED lights. Therefore, it is recommended to use specially designed voltage stabilizers or choose more durable lighting equipment in areas with unstable power supply.

(2) Strong electromagnetic interference areas: In some areas with high electromagnetic interference, such as some military facilities and radar stations, the intensity of the electromagnetic field is relatively high, which will interfere with the circuits of LED lighting fixtures, affecting their normal operation, and even causing LED lighting fixtures to malfunction or shorten their lifespan.

4. Environments requiring very uniform lighting

LED lighting fixtures generally have a relatively concentrated beam. Although this beam is very useful in some applications, LED lighting fixtures may not be suitable in environments that require uniform and widespread lighting. For example, the focusing effect of LEDs may cause some areas to be too bright while other areas are dark.

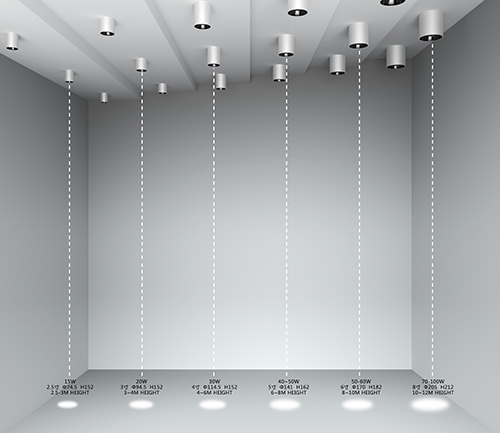

(1) High ceiling areas: In some commercial or industrial places with high ceilings, LED lighting fixtures may not provide sufficiently uniform lighting. Especially when using ordinary LED spotlights or spotlights, there may be some areas that are too bright and some areas that are too dark. Therefore, in such environments, you can consider using LED panel lights or other lighting equipment that can provide uniform lighting.

(2) Large exhibition halls or stages: For some places that require uniform lighting over a large area, such as large exhibition halls or stages, LED lighting fixtures may not be able to provide sufficiently uniform lighting effects. These places often require specially designed lamps, such as metal halide lamps or high-efficiency fluorescent lamps, to ensure the uniformity of the overall lighting.

5. Environments with special chemical substances

In some special working environments, the volatilization of chemical substances may affect the performance of LED lighting fixtures, especially highly corrosive chemical gases. Although the casing of LED lighting fixtures has a certain degree of protection, conventional LED lighting fixtures may be damaged in these harsh chemical environments.

(1) Chemical processing plants: In some chemical processing plants, such as fertilizer plants and petrochemical plants, due to high concentrations of corrosive gases, the casing and circuit components of LED lighting fixtures may be corroded, resulting in lamp failure or safety hazards. Therefore, in these highly corrosive environments, special anti-corrosion LED lighting fixtures should be selected or other types of lighting equipment should be used.

6. Excessive use of places

Although LED lighting fixtures have a long service life, in some places where they are frequently used, the lamps may be overused, resulting in heat dissipation problems or lamp degradation.

(1) Places where lights are turned on for a long time: In some places where lights need to be turned on for a long time, such as some shopping malls and factory workshops, LED lighting fixtures may overheat under continuous operation, resulting in performance degradation. Although LED lighting fixtures have better heat dissipation design than traditional lamps, long-term use may still affect the service life of the lamps.

What quality control measures are implemented during production?

Huari Lighting follows a strict quality management system throughout the entire production process. This includes raw material inspection, in-line testing during assembly, and 100% final product testing. Our factory is ISO 9001 certified, and all lights go through aging tests, surge protection tests, and lumen performance verification. Our advanced QC equipment ensures consistent quality, making us a reliable supplier for high-end markets and branded clients.